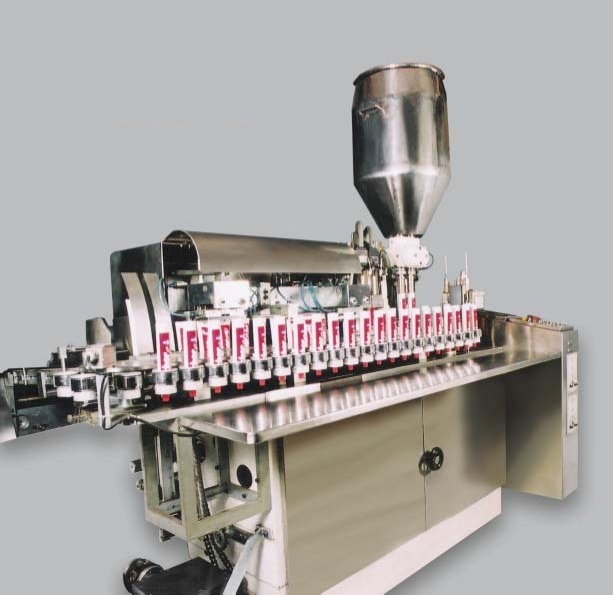

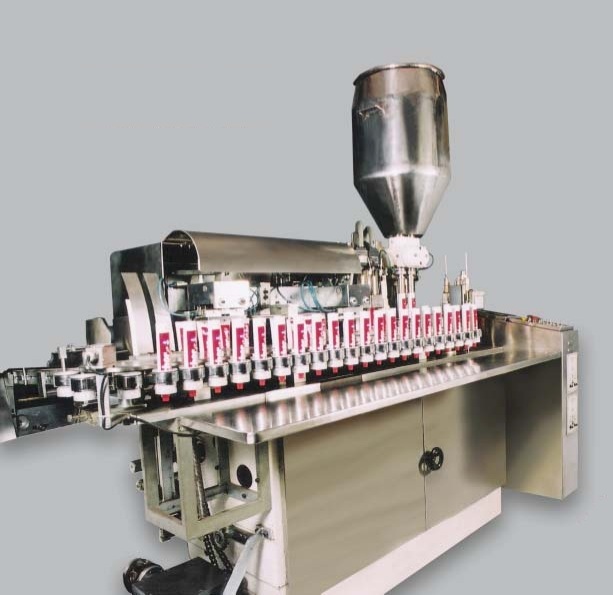

Automatic Tube Filling Machine

Automatic Tube Filling Machine Trade Information

- Minimum Order Quantity

- 1 , , Piece

- FOB Port

- Mumbai

- Supply Ability

- 3 Pieces Per Month

- Delivery Time

- 4-12 Week

- Packaging Details

- Seaworthy Wooden Pack

- Main Domestic Market

- All India

- Certifications

- GMP

About Automatic Tube Filling Machine

We are widely known as the manufacturer, exporter and supplier of world class packaging and processing machinery. We export our products to various locations worldwide. Our Automatic Tube Filling Machine is a precious tool for the pharma industry for packaging and filling the medicines and cosmetics in the tubes of dynamic sizes. Automatic Tube Filling Machine does not require manpower and run efficiently once instructed.

Features of Automatic Tube Filling Machine:

- High performance the major component of these machines

- Reliable to use for a long time

- Volumetric parameter used for ensuring accuracy in quantity

- High-quality of tube used for packaging the contents

ATF-I are designed to fill as well as seal aluminium / lami / plastic tubes at increased quickness. The machines are appropriate primarily for cosmetic and food & pharmaceutical industry. These can be employed for filling of ointment, gel, cream, paste, balm and other alike viscous products via means of a volumetric dosing method. The machines are of fully encircled construction with the rotary index table as well as single filling head. These are available in 3 configurations 1) for aluminum tubes 2) for lami / plastic tubes 3) for alu + lami tubes

Construction: Fully fenced

- Output: 2400 tubes in every hour for lami tubes

- 3000 tubes in each hour hour for alu tubes

- Operation System: Rotary Index Table, Single Head

- Tube Diameter: Least 12 mm to maximum 35 mm for alu, maximum 50 mm for lami

- Tube Measurement: Minimum 50 mm to maximum 220 mm

- Tube Loading: Automatic via a tube holding tray

- Tube Orientation: Automatic as well as electronically controlled

- Tube Cleaning: By compacted air blow

Product Hopper: S.S. 304, 50 liters capacity. (Water casing with electrical heating as well as hot water circulation drive optional)

Product Agitator: Slow speed agitator for rousing of product in hopper as an option

Filling Nozzle: Fixed spout, with tube lifting at filling place to lift up the hose so that nozzle gets introduced inside tube while filling. (Diving nozzle optional). NO FILL system has been united.

Tail Cutting: By suck-back technique (to avert dripping after the process of filling)

Dozing Range:

- a) 3 to 30 ml

- b) 30 to 100 ml

- c) 100 to 250 ml

Tube Sealing: Via hot air tool for plastic as well as lami tubes

Trim Left-over: Collected in an ampule on machine

Tube Ejection: Automatic, via a liberation chute for collection

By double fold as well as crumpling tool for aluminium tubes

Batch Code Embossing: In sealing jaws for lami / plastic tubes and in folding jaws for alu tubes

Efficient Tube Filling Performance

This automatic tube filling machine is engineered to deliver high-speed and accurate filling, achieving an impressive capacity of up to 60 tubes per minute. The robust stainless steel construction ensures durability, while the computerized control system streamlines operation for consistent output.

User-Friendly Control System

Equipped with a sophisticated Human Machine Interface, this machine offers a seamless interaction for operators. Its automatic grade and computerized features simplify adjustments, reduce downtime, and enhance overall productivity in a wide range of filling applications.

Ideal for Industrial Applications

With its generous dimensions, substantial weight, and pneumatic drive type, the machine provides stability and reliability in demanding industrial environments. Its 415V, 50Hz, 3 Phase configuration is compatible with standard power supplies used in Indian industries, making it a trusted choice for exporters and manufacturers.

FAQ's of Automatic Tube Filling Machine:

Q: How does the Automatic Tube Filling Machine operate?

A: The machine uses a combination of pneumatic drive and computerized controls via a Human Machine Interface, allowing for automated, precise filling and sealing of tubes with minimal human intervention.Q: What materials can be processed with this tube filling machine?

A: Constructed from stainless steel, the machine is suitable for filling a wide range of materials including creams, gels, pastes, and ointments, commonly found in the pharmaceutical, cosmetic, and food industries.Q: When should I schedule maintenance for optimal performance?

A: Routine maintenance should be carried out as per the manufacturer's recommendations, typically after every major production cycle or monthly, to ensure long-term reliability and compliance with the 1-year warranty conditions.Q: Where is this machine most commonly used?

A: This filling machine is ideally suited for industrial facilities, such as cosmetics, pharmaceutical, or FMCG manufacturing plants, where high-speed, large-volume tube filling is required.Q: What is the process of filling tubes with this equipment?

A: Tubes are automatically fed into the system, filled to the specified volume through precise pneumatic mechanisms, and then sealed and discharged, all managed by the computerized interface.Q: What are the benefits of using this automatic filling machine?

A: Key benefits include increased production efficiency, consistent fill accuracy, minimized product waste, reduced labor costs, and enhanced hygiene due to its stainless steel build.Q: How do I use the control system for product changeover?

A: Product changeover is managed easily through the Human Machine Interface, where operators can select preset filling parameters or adjust them as needed, supporting quick transitions between different tube sizes or product types.

- Minimum Order Quantity

- 1 , , Piece

- Supply Ability

- 3 Pieces Per Month

- Delivery Time

- 4-12 Week

- Main Domestic Market

- All India

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Tube Filling Sealing Machine Category

Tube Filling Machine

Price Range 450000.00 - 1850000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Color : Silver

Computerized : No

Power : 1.5 Watt (w)

Control Mode : Automatic

Automatic Tube Filling Sealing Machine

Price Range 350000.00 - 1850000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Color : Gray

Computerized : Yes

Power : 5 Watt (w)

Control Mode : Automatic